Smarter Machines, Anywhere: Edge AI Meets LoRaWAN

At this year’s The Things Conference in Amsterdam, participants were taken on a hands-on journey into the future of connected devices. The workshop, organized by Seeed, explored how Edge AI and LoRaWAN can spot problems before they happen—even in places where power or internet are hard to come by.

Why this matters

Many machines—from factory motors to farm pumps—can’t be monitored easily. Sending data to the cloud is often too expensive, too slow, or simply impossible where connectivity is poor. That’s where Edge AI (artificial intelligence that runs directly on a small device) combined with LoRaWAN (a low-power, long-range wireless network) comes in. Together, they allow devices to:

- Run for years on very little power

- Detect problems locally and instantly

- Keep data private and secure

- Work reliably in remote or harsh environments

- Scale to thousands of devices without huge costs

What the workshop built

Two practical mini-projects showed how this works in real life:

- Anomaly Vibration Sensor

- Using a small accelerometer, ESP32 chip, and LoRa module, participants built a sensor that learns what “normal” machine vibrations feel like.

- If something unusual happens (say, a fan wobbling), the AI flags it as “abnormal” and sends the alert via LoRaWAN to The Things Network.

- This simple setup can be applied to motors, bearings, pumps, and more—helping predict failures before they cause downtime.

- AI Vision Model

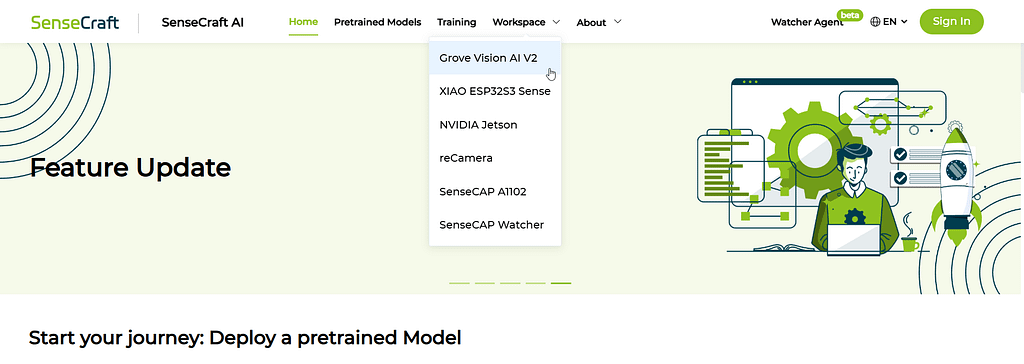

- With a Grove Vision sensor, participants trained a simple image classifier in minutes.

- For example: recognize if a fan is spinning, stopped, or not in the frame.

- No coding was needed—just snap 20–30 photos for each condition, click “train,” and deploy.

Real-world application: INOWISE.IO

INOWISE.IO uses Edge AI to detect vibration disturbances and irregularities in machine operation. Small sensors learn the normal vibration pattern of a machine. If an unusual movement appears—such as imbalance, loosened parts, or early signs of wear—the system instantly flags it. Because the analysis happens directly on the device, alerts are fast, reliable, and don’t require a permanent internet connection.

For factories and industrial sites, this means fewer unexpected breakdowns, less downtime, and lower maintenance costs—turning raw vibration data into clear insights for predictive maintenance.

Why this is exciting

What once required cloud servers, expensive data plans, and advanced AI skills can now be done on a palm-sized device, in just a few steps. By blending AI and LoRaWAN, predictive maintenance and smart monitoring are becoming accessible to anyone—whether you’re running a factory, a farm, or experimenting at home.

As the workshop wrapped up, one message was clear: this is just the beginning. With the right tools, Edge AI can bring intelligence to every corner of our physical world.

Comments are closed.